The Intriguing History and Success of LinkOne EPC.

What we now know and enjoy as LinkOne Software began as a software product called Imagelink, which was developed by Mincom, an Australian software company founded in 1979.

Mincom was a pioneer in enterprise software solutions, and the company was heavily focused on developing software for the mining industry, offering incredibly innovative solutions such as MIMS, Imagelink, and Minescape to streamline mining operations and increase productivity.

To the best of my knowledge, Imagelink’s origins can be traced back to the late 1980s and early 1990s.

As Mincom grew and matured, they discovered that there was a significant gap in the market for a comprehensive spare parts management system, having worked with a wide range of companies across most industries in the world.

In response to this need, Mincom set out on a mission to create a software product that would transform the way spare parts were managed and identified.

As a result, Imagelink was created, a game-changing software solution that would forever alter the landscape of spare parts management.

Mincom had developed an efficient solution to better manage and identify spare parts for equipment and assemblies.

Mincom’s very clever team of developers did such an excellent job with Imagelink that it would soon emerge as a truly pioneering graphical parts catalogue software designed for equipment maintenance and spare parts identification.

Mincom’s introduction of Imagelink revolutionised the mining industry. With its advanced features and user-friendly interface, this software quickly became popular among mining companies around the world.

Imagelink’s success did not happen overnight; it would have also been attributed to their hardworking team of consultants who were out and about around the world in the mid-1990s, actively demonstrating the Imagelink software to mining and other companies, showcasing its capabilities and benefits.

Back then, there were only two data sets on the Imaginelink demo product: an Army Camp Trailer and a Komatsu D375 bulldozer.

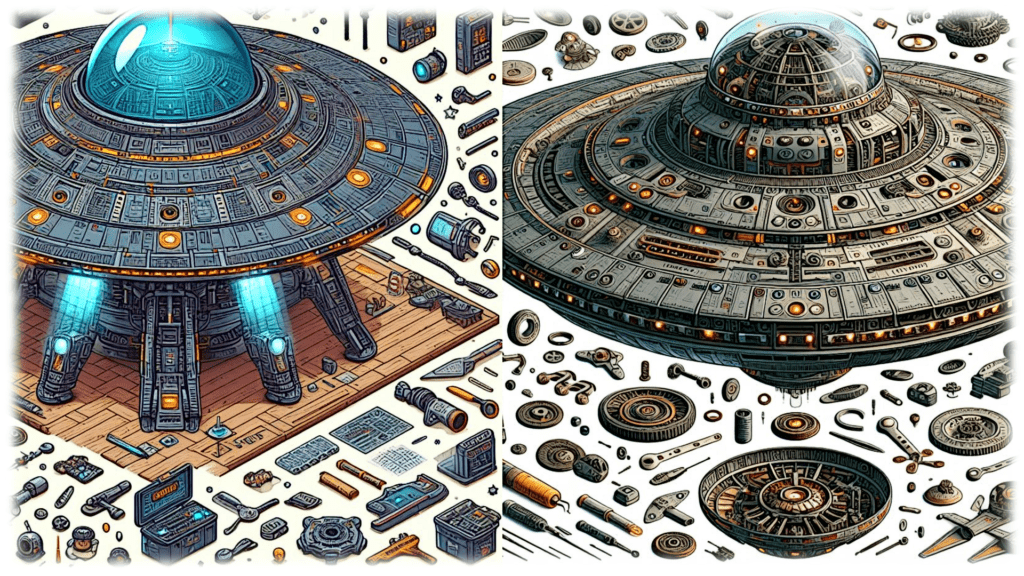

To be honest, the demo didn’t need much more; it was fascinating software, especially the way you could start with an image of the entire machine and then gradually pull it apart and then drill down into each assembly of the machine, right down to the bolts, nuts, and washers used to fasten a part into place.

Imagelink enabled users to use detailed visual catalogues of spare parts for a variety of equipment types. I thought the inclusion of an army camp trailer dataset was a nice touch that demonstrated its versatility beyond mining machinery.

The ability of Imagelink to visually represent complex machinery such as the D375 bulldozer was probably also important in its acceptance; after all, becoming firmly entrenched in the mining industry is what I imagine the Mincom team desired for Imagelink.

Imagelink demonstrations would astound attendees with its ability to explore machinery components, view part numbers, and access relevant documentation.

Imagelink transformed spare parts management by replacing traditional paper catalogues with interactive, visual representations.

It was a platform that could be used to streamline maintenance processes, reduce downtime, and improve the accuracy of part identification and ordering.

Mincom’s commitment to innovation made Imagelink an invaluable tool for industries that rely on heavy equipment.

Imagelink would eventually be rebranded as LinkOne.

Mincom’s LinkOne has evolved immensely over the decades and continues to do so.

LinkOne also has a connection to CAT SIS (Service Information System). CAT SIS existed before Imagelink/LinkOne, but it is historically linked to it.

Mincom entered into an agreement with Caterpillar in 1997 that benefited both parties. It provided Mincom with much-needed funds while also allowing Caterpillar to expand its software capabilities and improve its offerings in the heavy equipment industry.

Caterpillar gained access to Mincom’s expertise as part of this deal, which included the innovative Imagelink/LinkOne software.

Mincom was one of the world’s largest software companies at the time, and some argue that it was also the world’s largest software provider for the mining industry.

Although I’m not sure how CAT SIS benefited from Mincom’s software products, I imagine it was able to incorporate elements from Imagelink (which is now known as LinkOne) and possibly MIMS.

LinkOne’s graphical parts catalogue technology was quite popular at the time. Its visual representations of equipment components and efficient spare parts identification was at a level that I don’t believe anyone had ever seen before.

Without a doubt, one of LinkOne’s most significant advantages is its ability to generate very detailed visual catalogues of spare parts.

This feature enabled maintenance teams to quickly identify and locate the specific parts they required, saving time and effort.

Tradespeople no longer had to sift through hundreds of pages of extremely thick parts manuals to find the correct illustrated parts breakdown drawing, then write down all of the part numbers and quantities required, and then fax or email that information to the supplier to obtain a quote.

Instead, they could simply navigate LinkOne’s visual catalogue, zoom in on the necessary parts and you ticked the checkbox of the ones you needed.

In the early stages, once you clicked the checkboxes for the parts you wanted on the LinkOne drawing, many of us would simply print it out and use it to get a quote from the supplier.

As technology advanced and suppliers uploaded more comprehensive information, you could not only access all relevant parts information with a few clicks, but you could also access corresponding service book information, as well as price and availability information on the parts you needed.

LinkOne was only as good as the raw data provided by the equipment manufacturer; the more data uploaded, the more comprehensive the database of spare parts and other related information that users could access.

LinkOne would also integrate very smoothly with most CMMS solutions, and you could configure the integration so that you could select the parts you wanted from the LinkOne books, retrieve them into your CMMS, and pre-populate the material/spare parts information of your work order with direct purchase information.

Your CMMS would then validate this information, and if you had already catalogued specific part number selections, it would replace the direct purchase information with the inventory (SKU) information, and instead of a direct purchase, you would simply initiate a warehouse inventory request.

LinkOne’s intelligent search feature made it even easier to find specific parts based on their attributes or material categorisations.

LinkOne would help reduce mining equipment downtime by streamlining the spare parts management process.

Maintenance teams would be able to address equipment breakdowns and minimise the impact on production if they could quickly identify and order necessary parts.

The more popular LinkOne became, the more manufacturers and suppliers joined in to use the software.

In some cases, a manufacturer would use LinkOne to make their product information available to specific industry clients, while in other situations, they would use it to improve their own internal/in-house manufacturing productivity.

The Many Owners of LinkOne Over the Decades.

Mincom would continue to improve and refine LinkOne until it was acquired by Ventyx in 2006.

It was a little sad to see Mincom disappear from the world after being acquired by Ventyx, but that is how things go sometimes.

In any case, Ventyx was a global provider of enterprise software solutions, so LinkOne would be in very capable hands.

Mincom LinkOne would be rebranded as Ventyx LinkOne and integrated into the Ventyx product portfolio.

Four years later, in 2010, the ABB acquisition would occur. The massive Swiss-Swedish multinational corporation ABB purchased Ventyx.

As a result, Ventyx LinkOne was rebranded as ABB LinkOne and integrated into ABB’s industrial software solutions.

For approximately 8 years, ABB’s LinkOne would serve heavy equipment manufacturers, maintainers, dealers, and end users by facilitating efficient parts identification, content delivery, and maintenance processes.

Then Hitachi became very interested in ABB; in December 2018, Hitachi purchased slightly more than 80% of ABB’s power grids business, and LinkOne’s ownership changed once more.

Hitachi Energy was formed as a result of the ABB acquisition, then ABB LinkOne was renamed to Hitachi Energy LinkOne.

LinkOne is still going strong, impressing everyone who sees it.

The more advanced LinkOne becomes, the more precise and efficient it is at managing spare parts information, resulting in more streamlined maintenance operations across a wide range of industries.

LinkOne is a fantastic software product; it’s like having a virtual microscope at the tip of your mouse pointer, allowing you to examine every nook and cranny of a machine with ease.

You can spin assemblies around on an axis and zoom in as far as you need to, and you can do so in 2D or 3D. The 3D LinkOne books are simply incredible.

There is no limit to how comprehensive your LinkOne installation can be on-site. For example, in addition to linking Service Manual Information, you may decide to create a video of special welding instructions for a specific part and link it to the LinkOne drawing.

In addition, you can link work procedures and manufacturer-specific technical instructions.

It all depends on how much effort you are willing to put in. Creating comprehensive LinkOne books takes time and money, but it is an investment rather than a cost when you think about it.