Scheduled Work Percentage & Other Maintenance Performance Measures.

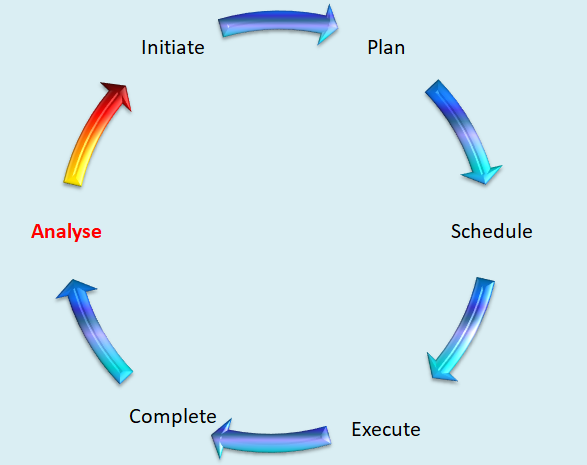

Measure

and review your maintenance process’s performance on a regular basis.

Use the metrics

you adopt such as Scheduled Work Percentage to identify areas for improvement

and ensure that results are managed to completion.

Schedule

compliance is a crucial lead metric, indicating the effort put into improving

the organization.

1.

Safety

Observations:

Conducting

regular safety observations fosters an interdependent safety culture. Effective

safety observations involve active listening and mutual concessions, allowing

maintainers to connect with leadership and continuously improve safety

practices.

2.

Leading

and Lagging Indicators:

Use

a combination of leading and lagging indicators to evaluate trends and outcomes.

Leading indicators predict future performance, while lagging indicators reflect

past performance.

Together,

they provide a comprehensive view of your maintenance process.

3.

Scheduled

Work Percentage:

Aim

for a 70% target for Scheduled Work Percentage, which measures the actual hours

recorded on scheduled work orders versus all work orders.

Ensure

all contractor work hours are recorded, even if they don’t have direct access to

the CMMS. Possible solutions include manual entry, developing a contractor

portal, or providing special CMMS access.

4.

Scenario

Analysis:

Analyse scenarios where scheduled work ratios and schedule compliance are low. Low scheduled work ratios may indicate neglect of scheduled work in favour of emergency tasks.

Good scheduled work ratios but low compliance may suggest equipment failures or incomplete work order processing. Investigate these scenarios to improve maintenance strategies and prevent future issues.

5.

Tips

for Good Scheduled Work Percentage Results:

a)

Avoid Overloading:

Don’t

overload your workforce with scheduled work.

Balance

is key to maintaining practical and effective maintenance schedules.

b)

Maintain Realistic Schedules:

Don’t

deliberately reduce scheduled work to improve compliance percentages. Stick to

tasks that are essential to your maintenance strategy.

c)

Conduct Root Cause Analysis:

Use

the ‘5 Whys Analysis’ on emergency work orders to identify underlying issues

and improve future schedules.

d)

Daily Queries:

Set

up daily queries in your CMMS to track work orders with actual hours entered

and their completion status.

This

helps ensure tasks are genuinely completed.

Top 8 Takeaways.

1)

Schedule Compliance: A key lead

metric indicating the effectiveness of maintenance scheduling.

2)

Safety Observations: Regular

observations foster a safety culture and improve communication between

maintainers and leadership.

3)

Leading vs. Lagging Indicators:

Combining both types of indicators helps evaluate trends and outcomes.

4)

Scheduled Work Percentage: A

metric to understand where maintenance hours are spent, aiming for a 70%

target.

5)

Contractor Work Hours: Ensure all

contractor hours are recorded, possibly through a contractor portal or manual

entry.

6)

Workforce Management: Avoid overloading

with scheduled work and ensure emergency tasks are analysed for future

improvements.

7)

5 Whys Analysis: Conduct this

analysis on emergency work orders to improve future schedules and equipment

reliability.

8)

Daily Queries: Set up queries to

track work order completion status and actual hours entered.

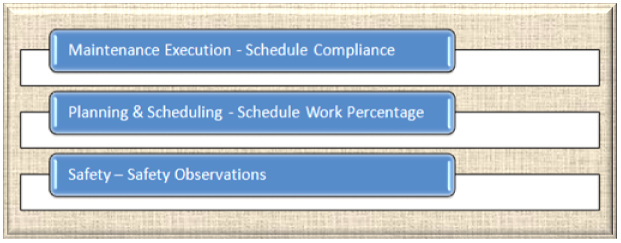

Using Leading & Lagging metrics when analysing Maintenance Performance

Your maintenance process’s performance must be measured and reviewed, and any chances for improvement must be pursued. Evidence that measurements are examined at regular meetings and results are managed to completion should be presented.

Leading Metrics

These metrics look at the effort you are putting in to improve your organisation and will indicate that some changes may be visible before they occur.

Schedule Compliance

Schedule compliance is an incredibly effective lead metric.

If your schedule compliance percentage is low, some causes may be:

- Scheduled work is not being completed due to an increase in the amount of emergency or breakdown work orders taking priority and hijacking the maintenance team’s efforts.

- Your company is yet to become proactive in its maintenance approach and is still very much in a reactive state.

- Too much scheduled work is being approved, highlighting inefficiency in scheduling meetings. This could involve a large number of unneeded and excessively frequent preventive maintenance jobs; maintainers should provide feedback to supervisors on these occurrences.

- Your equipment reliability is starting to drop away

- You may have had a high turnover of personnel in recent times, a large number of new employees who are still learning your equipment, and you may have relied extensively on contractors to replace unfilled positions on an as-needed basis.

- It’s also conceivable that you’re not gaining enough knowledge from your breakdown work. Although maintenance teams dislike having to respond to urgent failures at all hours of the day and night, it’s critical that you employ problem-solving skills to fully understand what’s going on and use this information to strengthen your preventative maintenance efforts. Consider using a tool like ‘Why Why Analysis.’

Safety Observations

When safety observations are conducted on a regular basis, it helps to foster an interdependent safety culture and an environment in which people believe they can speak freely and be heard often. They provide an opportunity for maintainers to connect with the leadership team, and the key to excellent safety observations, like with any other sort of human interaction, is mutual concessions/compromise; a little back and forth works great.

Those doing safety observations should keep in mind that they only have two ears and one mouth, therefore they should listen twice as much as they talk. Listen to what others are saying if you want the observation to be a positive experience for everyone involved. Active listening skills will reveal bits and pieces of knowledge that you can utilise to continuously improve safety and you might be surprised at how much you will learn.

LAGGING METRICS

These metrics show the outcomes of what’s been happening in your company and will record your actual performance after the events have happened.

Lagging indicators are always prompted by recent events and as such are a little more self-explanatory than leading indicators.

Lagging indicators work best when combined with leading indicators to evaluate trends and whether or not outcomes were met.

With the right technology and regular review sessions that evaluate leading and lagging signs, continuous improvement is possible.

Understanding SChedule work

70% is a

worthwhile initial target for Schedule Work Percentage.

The goal

of the ‘Scheduled Work Percentage’ metric is to fully understand where all your

maintenance departments work hours are actually being executed as apposed to

where you wanted them to be executed.

For this metric to be effective, you need to make sure all contractor

work hours are being entered on work orders.

It’s possible that a lot of your contractors won’t have CMMS access, so

you will have to develop a workaround solution to make sure these hours are

recorded.

Examples

of a workaround solution are:

·

Your staff will need to Manually

enter contractor actual hours against work orders

·

Develop a ‘Contractor Portal’

where their parent company can enter the required information into a software

product that is interfaced with your CMMS and populates the actual hour’s data.

·

Give all contractors a ‘special’

level of access to your CMMS

Tip:

I

recommend that you allow contractors to be able to enter comments against hour

entry data, for instance, if a job has required 50% more hours than planned/scheduled,

then a comment from the actual contractor that did the work would be of very

high value.

How is the Schedule Work Percentage calculated?

Schedule

Work Percentage = Actual Hours Recorded on Work Orders coded as ‘Scheduled’ divided

by the Actual Hours Recorded on all Work Orders.

Review Scenario 1: Your Scheduled Work Ratio was low for the last period and your schedule compliance was low.

This may

indicate that scheduled work is being neglected and emergency and other high

priority unplanned work is being done instead.

Review Scenario 2: Your Scheduled Work Ratio was good but you notice that your schedule compliance is low

This

tends to indicate that you’ve been able to execute the work on the schedule but

you have experience a large amount of equipment/component failures. This scenario should prompt investigation

by your reliability team. You may be on

the verge of experiencing more equipment reliability issues. This should prompt reviews of the

maintenance strategies associated with the equipment that failed during this

period, it’s possible that you’re not doing enough of the right type of

proactive tasks.

There is

also a chance that this scenario is a result of people partially processing

completed work, they’ve entered their actual hours against the work order

numbers but have not updated the status of the work order to ‘Complete’.

Here are a few tips relating to ‘Scheduled Work

Percentage’

1.

Don’t overload your workforce

with Scheduled Work; while doing nothing but ‘Scheduled Work’ could be

described as a ‘Maintenance Utopia,’ there are probably only a few scenarios on

this planet where that may be practical.

2.

Don’t deliberately load a smaller

than normal/expected percentage of scheduled work into the forthcoming

execution period just because you want to make your next schedule compliance

percentage looks a bit better. A big

chunk of your scheduled work is going to be tasks that are approved outputs of

your maintenance strategy, not doing these tasks will put at risk of unplanned

failures.

3.

Be sure to conduct ‘5 Whys

Analysis’ on as many of the emergency/breakdown work orders that occurred

during the execution period as possible.

What you learn from this analysis will help you produce more effective

schedules in the future and increase your equipment reliability.

4.

Set up a daily query within your

CMMS to show what work orders have had actual hours entered against them and

what the relating completion status is.

The Maintenance Supervisor should be able to indicate if those tasks are

actually complete or not.