Inspection and Maintenance Management

Inspection and Maintenance Management is a critical discipline in heavy industrial environments such as mining, mineral processing, manufacturing, energy generation and large‑scale infrastructure.

In these sectors, assets operate under extreme loads, harsh climates and continuous production pressures. The consequences of failure, financial, operational, environmental and human, are significant.

A mature inspection program provides the foresight, control and operational intelligence required to keep complex systems safe, reliable and economically sustainable.

The Strategic Role of Inspections In Industrial Operations.

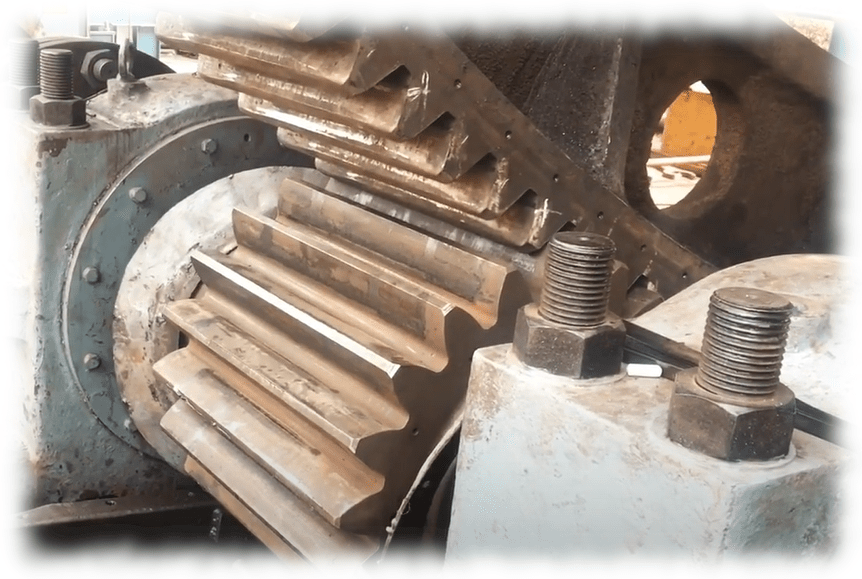

Inspections form the backbone of predictive and preventive maintenance, enabling organisations to detect early signs of degradation long before they escalate into failures.

In Australian mining and processing environments, where equipment faces dust, heat, corrosive materials and heavy mechanical stress, inspections allow teams to identify wear patterns, alignment deviations, lubrication breakdowns and structural weaknesses that compromise asset integrity.

This proactive posture shifts organisations away from reactive “break–fix” cycles and toward a culture of foresight and controlled risk, resulting in improved uptime, extended asset life and more predictable maintenance workloads.

Advanced Technologies Transforming Inspection Management.

Modern inspection programs are increasingly supported by intelligent technologies that enhance accuracy, speed and predictive capability.

- IoT condition monitoring sensors for real‑time vibration, temperature and pressure data.

- AI‑driven predictive analytics that forecast failures before they occur.

- Drones and robotics for hazardous or hard‑to‑reach inspections.

- Machine learning anomaly detection based on historical patterns.

- Digital twins that simulate asset behaviour under different conditions.

These technologies elevate inspections from periodic snapshots to continuous operational intelligence.

Compliance, Standards and Regulatory Assurance

Australian Requirements.

In Australia, heavy industry is governed by a robust regulatory ecosystem designed to protect workers, communities and the environment.

Inspections are a primary mechanism for demonstrating compliance with:

- Work Health and Safety (WHS) Act and Regulations across all states and territories.

- Safe Work Australia Codes of Practice, including Managing Risks of Plant in the Workplace.

- AS/NZS 3788 for pressure equipment inspection.

- AS/NZS 3000 (Wiring Rules) for electrical safety.

- AS 2550 series for cranes, hoists and lifting equipment.

- AS/NZS ISO 55001 for asset management systems.

- Mining-specific legislation, such as the NSW Work Health and Safety (Mines and Petroleum Sites) Regulation 2022 and QLD Coal Mining Safety and Health Act.

- Environmental Protection Acts at state and federal levels.

These frameworks require organisations to maintain documented inspection regimes, demonstrate risk-based decision-making and ensure plant and equipment remain safe for operation.

Global Standards.

Alongside Australian requirements, many organisations also align with:

- ISO 55000 series for asset management.

- OSHA principles for safety management.

- API standards in oil and gas.

A strong inspection regime ensures compliance, avoids penalties and maintains operational licence to operate.

Financial Impact: ROI, TCO & The Economics Of Proactive Maintenance.

Inspections are not just a technical necessity, they are a financial strategy.

Organisations that invest in proactive inspection programs consistently see returns through:

- Reduced unplanned downtime.

- Lower emergency repair costs.

- Extended asset lifespan.

- Optimised spare parts inventory.

- Improved total cost of ownership (TCO).

Quantifying ROI helps maintenance leaders justify budgets and demonstrate the economic value of disciplined inspection management.

Real‑World Challenges and Common Pitfalls

Even with strong frameworks, inspection programs often face operational challenges:

- Resistance to change when shifting from reactive to proactive maintenance

- Inconsistent inspection quality due to inadequate training

- Data silos that prevent insights from being shared

- Over‑inspection that wastes resources

- Under‑inspection that leaves critical risks undetected

Addressing these challenges requires leadership, clear processes and a culture that values accuracy over speed.

Safety, Human Factors and Psychological Reliability.

Inspections are a frontline defence against workplace accidents. They identify hazards such as faulty wiring, structural instability, leaks and guarding failures.

But inspection quality is also shaped by human factors:

- Fatigue and cognitive load

- Ergonomic design of inspection tools

- Psychological safety that encourages honest reporting

A mature inspection culture recognises that people, not just tools, determine reliability.

Environmental and Sustainability Considerations.

Inspections play a crucial role in environmental protection and ESG performance. They help detect:

- Leaks that could contaminate soil or waterways.

- Inefficient equipment consuming excess energy.

- Dust, emissions, or noise exceedances.

- Wasteful or unsafe material handling practices.

In Australia, inspections support compliance with state EPA requirements and the Environment Protection and Biodiversity Conservation (EPBC) Act, helping organisations avoid environmental harm and regulatory action.

Data Analytics, Reporting and Decision Intelligence.

Inspection data becomes exponentially more valuable when analysed effectively. Advanced maintenance teams use:

- Trend analysis to track degradation

- Root cause failure analysis (RCFA) to eliminate recurring issues

- MTBF and MTTR metrics to measure reliability

- Dashboard visualisation for real‑time decision-making

This transforms inspections from checklists into strategic intelligence.

Supply Chain and Vendor Integration.

Inspection findings often trigger procurement actions. Effective programs integrate:

- Vendor-managed inspections.

- Just‑in‑time parts

- Maintenance–supply chain coordination.

This alignment reduces delays, prevents stockouts and ensures repairs occur when needed.

Metrics, KPIs and Continuous Improvement.

High-performing organisations measure inspection effectiveness using:

- Inspection completion rates.

- Defect detection accuracy.

- Overall equipment effectiveness (OEE).

- PDCA improvement cycles.

These metrics ensure inspection programs evolve with operational needs and technological advancements.

Conclusion.

Inspection and Maintenance Management is far more than a technical function, it is a strategic discipline that underpins safety, reliability, sustainability and financial performance in heavy industry.

By combining rigorous inspection practices with advanced technologies, strong governance, Australian regulatory compliance, human‑centred design and continuous improvement, organisations can build operations that are safer, more efficient and more resilient.

A mature inspection program doesn’t just prevent failures. It creates a foundation for operational excellence.