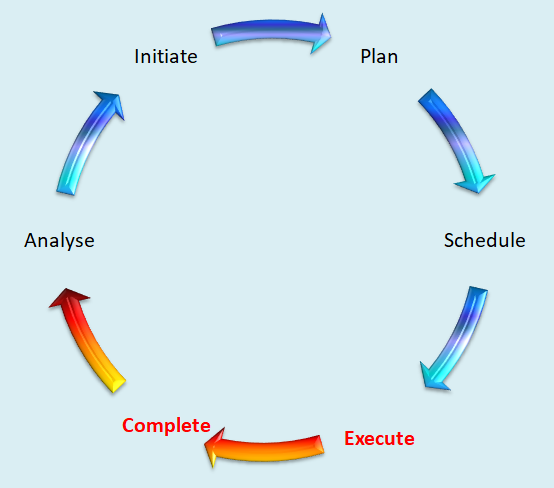

Execute And Complete Maintenance Work Orders.

Effective maintenance management is crucial for the smooth operation of any facility. This article outlines the key steps to ensure quality work orders and efficient maintenance processes.

1. Preparation for Maintenance.

Before

starting any scheduled maintenance work, it’s essential to:

·

Modify Work Order Status: Update

the status to reflect that the work is in progress.

·

Review Work Pack: Allocate time

to read through the work pack and provide input on duration and resource

estimates.

·

Obtain Spare Parts: Ensure all

necessary spare parts are obtained and inspected.

2. Executing Maintenance Tasks.

During

the maintenance work, focus on:

·

Monitoring Tasks: Keep track of

the progress and provide feedback.

·

Managing Shift Handovers: Ensure

smooth transitions between shifts.

·

Commissioning Equipment: Work

with production to commission equipment after maintenance.

3. Completing Work Orders.

Accurate

completion of work orders is vital for continual improvement:

·

Record Resources and Duration:

Document the resources used, including contractors, spares, and internal labour.

·

Note Delays and Problems: Record

any delays or issues encountered.

·

Clean Work Area: Ensure the work

area is cleaned and tools are returned.

4. Review and Close Work Orders.

After

completing the tasks:

·

Update Work Orders Daily: Provide

full details of the job performed.

·

Review by Supervisor: The

supervisor should review all completed work orders and note any delays or

problems.

By

following these steps, organizations can ensure high-quality maintenance work,

leading to improved reliability and performance.

Execute

The execute step involves completing the maintenance work according to the approved schedule, which includes preparing equipment for maintenance, monitoring tasks, providing feedback on work progress, managing shift handovers and additional work, and in conjunction with production, commissioning equipment after the maintenance work is finished.

Prior to performing any scheduled maintenance work, it is critical to modify the status of work orders that are going to be performed to reflect that the work is in progress. Prior to beginning work, time should be made out to read through the work pack and provide input on the duration and resource estimates; are they adequate to perform the work efficiently? Any spare parts required for the job are obtained and inspected.

Complete Work

Correctly completing work orders strives to capture useful information from maintenance tasks performed in order to enable continual improvement. It includes recording the resources used and duration to complete the work, including contractors, spares, rotables, internal labour, and shared equipment; recording delays or problems, relevant maintenance history, and failure coding to enable future troubleshooting and reliability analysis; cleaning the work area; and returning tools, equipment, unused materials, warranty, and repairable items, which is critical for accurate cost and performance measurement.

Completed work orders should be updated and closed off on a daily basis, with full details of the job performed provided. Any faults or problems with the scope of work should be noted on the work order or work pack, which should then be reviewed by the supervisor and sent back to the planner. The supervisor should review all completed work orders and make sure the maintainer has indicated any delays encountered during the task.

The CMMS Roles of the Maintenance Supervisor

- Review Work Requests daily and ensure the correct asset reference is assigned

- Update estimated cost field & action emergency or urgent work.

- Create work orders for any urgent tasks to be carried out.

- Release purchase requisitions raised by maintainers as required

- Assign work to work crew.

- Ensure work centre resource availability is correct in the CMMS

- Liaise with Scheduler over matters relating to availability of labour, assist in establishing the scheduled maintenance and attend weekly scheduling meeting.

- Create purchase requisitions for Supplementary labour if required.

- Assign scheduled work to the appropriate people in the work crew.

- Supervise work as required.

- Ensure quality of work.

- Ensure work orders are completed and any future work is identified.

- Ensure time confirmations are carried out in the CMMS.

- Review work orders and ensure maintainers are creating additional work requests for additional work required and ensure feedback is being provided to the planner.

- Ensure appropriate history is recorded on completed work orders

- Technically complete work orders as completed.

- Ensure any removed repairable equipment or components have all fluids drained, thoroughly cleaned and taken to warehouse.

- Attend weekly KPI review meeting.

- Initiate changes to maintenance strategies when maintainers have marked up problems with preventive maintenance work orders; provide this information to reliability engineer.

- Identify opportunities for new maintenance strategies when the same corrective task is being repeated often and provide this information to the reliability engineer.

- Monitor actual work costs against the budget and advise superintendent of possible over-runs. Explain cost variances.

- Initiate maintenance bill of materials changes required and pass information onto maintenance planner.

- Initiate correction of any missing/inaccurate asset master data and advise Maintenance Planner.

- Initiate correction of an inaccurate inventory records and pass onto Store Supervisor.

[…] Execute & Complete Maintenance Work – CMMS SUCCESS. Execute and Complete Maintenance Work. Get the most out of your Assets – CMMS SUCCESS. Get the most out of our assets. Your boss needs solutions not problems – CMMS SUCCESS. Dealing with complaints at work. Asset Management Training for Mainteannce Planners. Asset Management Training for Planners – CMMS SUCCESS. Operations Run down and Start up Plans. Asset Management Tips and Tricks. Asset Management Data Quality. Generic Equipment Servicing Information – CMMS SUCCESS. GENERIC SERVICING. […]