Kenworth T880 Tipper Asset Management Plan Details.

This page is a continuation of the Truck Maintenance Management Page and it is here that I will be taking you deeper into the asset management requirements of the 2021 Kenworth T880 Tipper:

1. Asset and Component Identification and Documentation: The first step in effective asset management is to create a detailed record of your truck.

a. This includes noting down the Vehicle Identification Number (VIN), model, year, and specifications.

b. Keeping a comprehensive record will help you track the truck’s history and identify any specific components that may require attention or replacement.

2. Maintain Relevant Documents: It is essential to maintain a digital or physical folder with all relevant documents related to your truck.

a. This includes purchase records, maintenance history, warranties, and any other important documents.

b. Having easy access to these documents will streamline maintenance processes and assist in warranty claims.

3. Asset/Component Lifecycle Planning: Understanding the expected lifespan of your Truck is crucial for effective asset management.

a. By analysing usage patterns and industry standards, you can plan for replacement or upgrades in a timely manner.

b. This proactive approach will help you avoid unexpected breakdowns and maximize the truck’s overall lifespan.

4. Conduct Regular Inspections: Routine visual inspections of your truck are essential for identifying signs of wear, leaks, or damage.

a. Inspect the entire vehicle, including tires, brakes, lights, and fluid levels.

b. Regular inspections will allow you to address any issues promptly, preventing them from escalating into costly repairs.

5. Scheduled Maintenance: Following the manufacturer’s recommended maintenance schedule is vital for the optimal performance of your T880 Dump Truck.

a. Regularly service engine oil, filters, coolant, and other fluids as per the prescribed intervals.

b. Additionally, grease chassis components as needed to ensure smooth operation and prevent premature wear.

6. Full Spectrum Oil Analysis: Periodically taking hot samples of your compartment oils and sending them to a reputable lab for analysis can help assess component health.

a. Oil analysis detects early signs of contamination or mechanical issues, allowing you to address them before they cause major damage.

b. Ensure you follow safety guidelines when performing this task.

7. Oil Compartment Changes: Replace all compartment oils at the prescribed intervals in your manual. Check for updates on the Kenworth site or by calling in to your local Kenworth dealer.

8. Tyre Management: Monitoring tire pressure and tread depth is essential for both safety and fuel efficiency.

a. Regularly check tire conditions and rotate them to ensure even wear. Promptly replace worn-out tires to maintain traction and stability.

b. Proper tire management contributes to fuel efficiency optimisation and extends tire lifespan.

c. I developed a separate article that is purely focussed on Tyre Management and Tyre Management Software.

9. Fuel Efficiency Optimisation: Using quality fuel and additives can improve your truck’s fuel efficiency.

a. Monitor fuel consumption trends to identify any anomalies or potential issues.

b. By optimising fuel efficiency, you can reduce operational costs and minimize environmental impact.

10. Telematics System: Installing a telematics system in your truck allows you to monitor its performance in real-time.

a. Track fuel usage, idle time, and receive maintenance alerts. Telematics provide valuable insights into your truck’s operation, enabling you to make data-driven decisions and optimise its performance.

b. Telematics combine telecommunication and informatics to collect, transmit and analyse data from vehicles and equipment.

c. Telematics systems use GPS technology, onboard diagnostics, and sensors to gather information on your Kenworth at you are out there doing the work that pays your bills.

d. This helps you optimise operation, improve safety, reduce costs, and enhance efficiency.

Telematics Systems Options.

Samsara: Offers a dispatch optimisation, real-time tracking, and predictive departure times based on traffic conditions.

Teletrac Navman is another good option, it provides customisable truck tracking systems for fleet management.

11. Warranty Management: Understanding the warranty coverage and expiration dates is crucial for effective asset management.

a. Familiarize yourself with the terms and conditions of the warranty and file claims promptly when needed.

b. Proper warranty management can save you from unnecessary expenses and ensure timely repairs.

12. Emergency Preparedness: Equipping your truck with emergency tools and equipment is essential for unforeseen situations.

a. Keep items such as fire extinguishers, warning triangles, first aid kits, and snake bite kits readily available.

b. Additionally, always carry an ample supply of fresh drinking water and non-perishable food in case of breakdowns in remote locations.

13. Environmental Compliance: Adhering to emission standards and regulations is not only a legal requirement but also contributes to environmental sustainability.

a. Properly dispose of hazardous materials such as oil and coolant to prevent pollution.

b. Complying with environmental regulations demonstrates your commitment to responsible asset management.

14. Record Keeping: Maintaining accurate records of all maintenance and repairs is crucial for effective asset management.

a. Use digital tools or software to streamline record-keeping processes and ensure easy access to information.

b. Detailed records help track costs, identify recurring issues, and assist in making informed decisions.

15. Component Replacement Strategy: Planning for major component replacements based on usage hours or mileage is essential to avoid unexpected breakdowns.

a. Budgeting for these replacements in advance allows you to allocate resources efficiently and minimize downtime.

b. Regularly assess the condition of critical components such as the engine and transmission to plan for replacements proactively.

16. Stay Up-To-Date with all Safety Upgrades: Consider implementing safety enhancements in your truck, such as collision avoidance systems, backup cameras, and improved lighting.

a. Regularly inspect safety features like seat belts and airbags to ensure they are in proper working condition.

b. Prioritising safety upgrades enhances driver and road safety, reducing the risk of accidents.

It’s a lot to take in but it’s worth it.

Implementing a comprehensive asset management plan for your 2021 KENWORTH T880 Dump Truck is essential for its optimal performance, longevity, and cost-effectiveness.

By having 16-point plan such as this, you can ensure that your Kenworth Truck operates efficiently, minimize downtime, and maximize its overall lifespan.

Stay proactive, prioritise regular maintenance, and leverage technology to streamline asset management processes. By doing so, you will reap the benefits of a well-maintained and reliable truck.

Preventive Maintenance for your X15 Cummins Engine.

Maintaining the optimal performance of your Cummins X15 engine requires correct interval, competently performed maintenance.

You can make sure your engine runs at its best and increase its longevity, get the fuel efficiency you need, and dependability you deserve by adhering to a well thought out maintenance management program.

Cummins X15 engine basics.

a. Stick to the recommended oil change schedule set by Cummins.

b. For the best lubrication and wear-and-tear protection, use premium diesel engine oil with the right viscosity.

c. Regular inspection and replacement of fuel filters are part of fuel system maintenance.

d. Maintaining a clean fuel system will help you avoid injector issues and preserve maximum fuel efficiency.

e. Regular checks of the coolant levels and verification of the proper antifreeze concentration are part of cooling system maintenance.

f. Check for any damage or leaks that could compromise the cooling system’s functionality on the radiator, belts, and hoses.

g. Replace the air filters according to recommended intervals to maintain clean engine airflow.

a. Additionally, to keep debris out of the engine, clean or replace the parts of the air intake system on a regular basis.

Turbo Inspections.

You will need to check the turbocharger for damage, leaks, and excessive wear on a prescribed basis.

To you’re your engine operating effectively and efficiently, make sure the turbo properly cooled and lubricated.

Maintenance of the Exhaust System.

Check the exhaust system for leaks, holes and corrosion on a reasonably regular basis.

Regular inspection of the Diesel Particulate Filter is required.

You will need to give it a good clean as well to prevent blockages that may impair engine performance.

The System for Recirculating Exhaust Gas.

Usually referred to as the ‘EGR’, this system requires cleaning of the Exhaust Gas Recirculating (EGR) valves and coolers will ensure optimal performance and prevent carbon build-up.

Keep an eye on the EGR system’s performance to guarantee optimal engine efficiency.

Valve Adjustment.

Adhere to the recommended schedule for valve lash adjustment to guarantee correct valve operation. In addition to increasing engine efficiency, correctly adjusted valves lower the possibility of damage.

Crankcase Ventilation Systems.

Make sure the crankcase is adequately ventilated to avoid oil contamination. Parts of the crankcase ventilation system should be cleaned or changed as needed.

Drive belts and pulleys.

These should be routinely inspected for wear and misalignment. Replace any worn parts right away to avoid damaging the engine or causing the belt to slip.

Battery maintenance.

Check the battery terminals, connections, and cables on a regular basis. Maintain clean, fully charged batteries for optimal electrical system performance and starting.

Engine wiring and sensors.

Ensure that engine sensors (temperature, pressure, etc.) are accurate on a regular basis and replace them as necessary. Inspect wiring harnesses for any damage that might impair sensor readings or engine performance.

Engine Compression Testing.

Conduct compression tests on a regular basis to assess the overall condition of your Cummins X15 engine. This test can help detect potential issues before they become more serious.

Engine Oil Analysis.

Check engine oil samples on a regular basis for contamination or wear indicators. Based on the results of the analysis, modify your maintenance schedule as needed.

Engine Coolant Additives.

Use approved coolant additives to prevent corrosion and cavitation in your engine. These additives can prolong the life of your cooling system and shield it from potential harm.

Engine Management Software Updates.

Install any recommended updates and react fast to any recalls to keep your engine control software current.

This guarantees optimal engine performance while simultaneously reaping the benefits of any gains in efficiency.

OEM/Professional Inspections.

However, if you are qualified and have the right tools, you can perform some or all of the maintenance on your own.

To conduct expert engine inspections, consult with certified Cummins technicians on a regular basis.

To find error codes and identify possible issues, they can make use of diagnostic tools.

Have the engine of your truck inspected by a professional once a year, as this is what they do for a living.

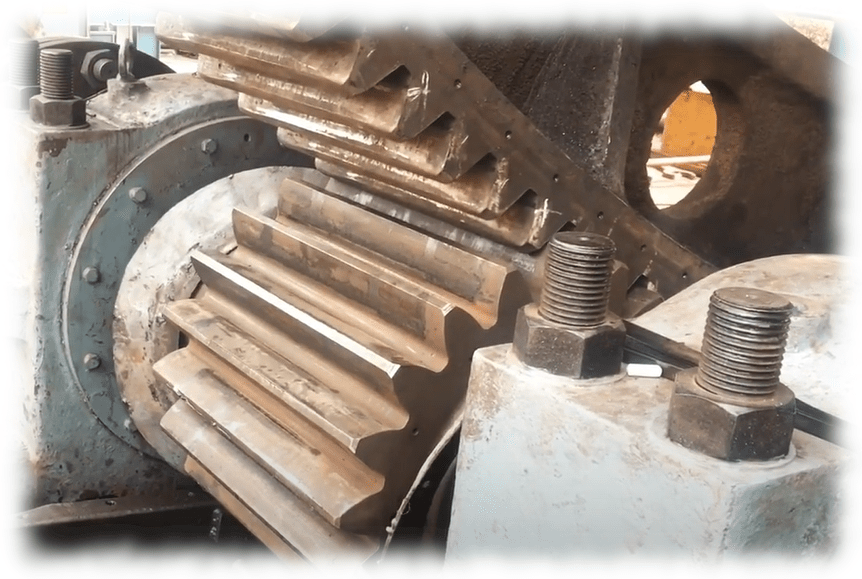

Preventive Maintenance for your 7 Speed Allison Transmission.

Your Allison 7-speed automatic transmission’s hassle free longevity and sustained optimum performance are largely dependent on proper maintenance.

You can save money on repairs and maintain the smooth operation of your transmission by adhering to the manufacturer’s instructions and performing routine inspections and preventive measures.

I’ll go over some maintenance advice for an optimally maintained Allison transmission below.

Fluids and Filters: Regular fluid and filter changes are among the most important parts of transmission maintenance.

It is imperative to adhere to the recommended fluid change intervals provided by the manufacturer.

For optimal performance and longevity, use transmission fluid approved by Allison.

Correct Interval fluid changes guarantee smooth operation and help prevent wear.

Fluid Analysis: Use the Prognostics feature, if your Allison transmission has one, to keep an eye on the state of the transmission fluid.

Examine fluid samples on a regular basis for indications of contamination or wear.

By taking a proactive stance, you can prevent possible problems from getting worse and prolong the life of your transmission.

Maintain the Cooling System: For optimum performance, transmission cooling must be done properly.

Check for leaks or obstructions on a regular basis in the transmission cooler, lines, and hoses.

Verify that there is sufficient airflow for cooling and that the cooling system is operating as intended.

Take quick action to resolve any cooling system problems to avoid overheating and possible transmission damage.

Electrical Connections and Wiring: Look for any indications of damage on the Allison transmission’s electrical connectors and wiring.

Make sure there are no corrosion or loose connections.

It’s critical to fix any wiring or connector issues as soon as possible because poor electrical connections can cause transmission performance problems.

Inspect the torque converter: Check your torque converter frequently for any leaks or strange noises.

Take quick action to fix any problems you find, such as fluid leaks or strange noises, to stop the transmission from getting worse.

For smooth and effective operation, a torque converter in good condition is essential.

Seals and Gaskets: Check your Allison transmission’s seals and gaskets for any indications of leaks. Replace worn-out or broken parts to stop fluid leaks and possible transmission damage.

Maintaining the integrity of your transmission requires routine seal and gasket inspection and maintenance.

Transmission Mounts: Verify that the alignment and mounting of your transmission are correct.

Examine the transmission mounts for indications of wear or damage.

Your transmission’s overall performance may be impacted by excessive vibrations and misalignment caused by damaged mounts.

As soon as possible, replace any damaged mounts to preserve the best transmission performance.

The Shift Solenoids and Valves: Give your Allison transmission’s shift solenoids a routine inspection and cleaning.

These elements are essential to the process of shifting. Resolve any valve body problems as soon as possible to guarantee precise and seamless shifting.

Maintaining shift solenoids and valves on a regular basis helps avert problems with transmission performance.

The Transmission Control Module (TCM): Updating your TCM software will guarantee optimum performance. For software updates, adhere to the manufacturer’s recommendations and fix any error codes right away.

Maintaining the TCM’s optimal condition is critical to the Allison transmission’s overall performance as it regulates a number of transmission functions.

I’ll have a separate section at the bottom of this article dedicated to TCM.

Maintain the Transmission Cooler: Change the transmission cooler when necessary or clean it on a regular basis.

Make sure there’s enough airflow to provide cooling. Overheating and possible transmission damage can result from a blocked or broken transmission cooler.

To maintain the ideal transmission temperature, routine maintenance of the transmission cooler is essential.

Transmission Lines and Fittings: Check for leaks or corrosion in the transmission lines and fittings.

Promptly replace any corroded or damaged lines or fittings to avoid fluid loss and possible transmission damage.

Maintaining the integrity of your Allison transmission requires routine inspection of the fittings and transmission lines.

Correct adjustment of the Shift Linkage: To ensure accurate and seamless shifting, make sure your shift linkage is adjusted correctly.

If you have trouble shifting, you might need to adjust the shift linkage.

Optimising transmission performance is maintained with the help of proper shift linkage adjustment.

Software Updates and Recalibration: For software updates and recalibration, adhere to the manufacturer’s instructions.

Updating your transmission software will guarantee optimal performance from your Allison transmission.

In order to fix any performance problems or improve the transmission function, calibration might be required.

Professional Inspections: For professional inspections and maintenance, regularly consult with certified Allison technicians.

Businesses with expertise in Allison transmissions, such as Penske, can offer professional guidance and services.

In order to preserve the longevity of your transmission and stop additional damage, take quick action to address any performance issues.

Prevent Your Transmission From Overheating: Throughout operation, keep an eye on the transmission’s temperature to avoid overheating.

Extended overheating may cause serious harm to the transmission.

If you find that your transmission is operating hotter than usual, fix the problem right away to avoid having to pay for expensive repairs later on.

Documentation and Record Keeping: Keep thorough records of all the upkeep and repairs done on your Allison transmission.

Maintain a record of all fluid changes, inspections, and modifications.

You can keep track of your transmission’s history and maintenance requirements with the aid of this documentation.

The Transmission Control Module (TCM).

A vital component that frequently goes unnoticed but is essential to the flawless operation and best possible performance of your truck’s automatic transmission is the Transmission Control Module (TCM).

The TCM, which functions as the “brain” of the transmission system, controls many facets of gearbox operation to guarantee seamless gear changes, peak performance, and fuel economy.

Inputs and Sensors.

The TCM gets data from a number of sensors that give it vital information for making decisions, including:

Speed sensors: By tracking the rotation of the wheels and the vehicle’s speed, these sensors enable the TCM to select the right gear for the current speed.

Throttle Position Sensor: By detecting the throttle’s position, the TPS allows the TCM to modify shift points in response to throttle input.

Engine RPM Sensor: The TCM can calculate the ideal gear-shifting timing for seamless acceleration by monitoring engine speed.

Transmission Fluid Temperature Sensor: By keeping an eye on the fluid’s temperature, this sensor makes sure it remains within the ideal operating range.

Brake Light Switch: The TCM is able to synchronise gear changes and braking with the status of the brake pedal.

Gear Selector Position Sensor: This sensor lets the TCM engage the right gear by figuring out which gear to select.

Shift Strategy and Adaptation.

To guarantee optimum performance, the TCM applies pre-programmed shift strategies based on driving conditions:

Shift Points: Based on variables like engine load, throttle input, and vehicle speed, the TCM decides when to upshift or downshift.

Adaptive Learning: The transmission’s performance is optimised for the driver’s preferences as the TCM learns from driving conditions and habits over time to modify its shift patterns.

Fail-Safe Mode: To protect the transmission and the car from additional harm in the case of a sensor failure, the TCM flips to a default mode.

Communication with Other Modules.

In order to guarantee smooth system coordination, the TCM is also essential for communication with other control modules:

Engine Control Module (ECM): To enable effective power delivery, the TCM and ECM collaborate to coordinate engine and transmission functions.

Anti-lock Braking System (ABS): To guarantee secure braking and stability during gear changes, the TCM talks with the ABS.

Vehicle Stability Control (VSC): To improve stability during gear changes and offer a smooth and controlled driving experience, the TCM collaborates with the VSC.

Shift Solenoids and Valves.

The transmission’s hydraulic valves and shift solenoids are managed by the TCM, allowing for exact gear engagement.

Shift Solenoids: To enable seamless gear shifts, these solenoids control fluid flow to engage or disengage clutches.

Pressure Control Solenoids: These solenoids allow the TCM to regulate line pressure, resulting in seamless and reliable shifts.

Lockup solenoids: By activating the torque converter lockup clutch, these solenoids lower heat production and increase fuel economy.

Diagnostic Capabilities and Maintenance.

The TCM records fault codes and keeps track of the transmission’s condition, enabling mechanics to identify and resolve any problems:

Diagnostic Capabilities: By retrieving fault codes from the TCM using specialised tools, mechanics can gain important information about possible transmission issues.

Upkeep and Updates: Verifying TCM connections, wiring, and software updates are all part of routine maintenance. Updates to the software fix known problems and boost efficiency.

Fail-Safe Mode: The TCM switches to a fail-safe mode in the event of a critical fault. This limits transmission operation to safeguard components and illuminates the transmission warning light.

Overall Importance of the TCM.

In order to maximise driving comfort, minimise wear on transmission components, and ensure effective power delivery, the TCM is essential.

The longevity and dependability of the transmission depend on its correct operation.

To put it briefly, the Transmission Control Module (TCM) is an advanced controller that coordinates the complex motion of solenoids, clutches, and gears in the automatic transmission of your truck.

The transmission control module (TCM) facilitates seamless gear shifts, optimal performance, and fuel efficiency by controlling inputs, shift strategies, communication with other modules, and diagnostic capabilities.

The TCM’s optimal performance depends on routine maintenance, which includes software updates. This prolongs the life and dependability of the truck’s transmission.

Conclusion.

There is a lot to remember, that is for sure and this is why I believe using a CMMS for all of this work makes so much sense.

I’ve put together a document about doing this for Truck Owner/Operators using one particular CMMS option that is called Fiix, you can read that via this link.