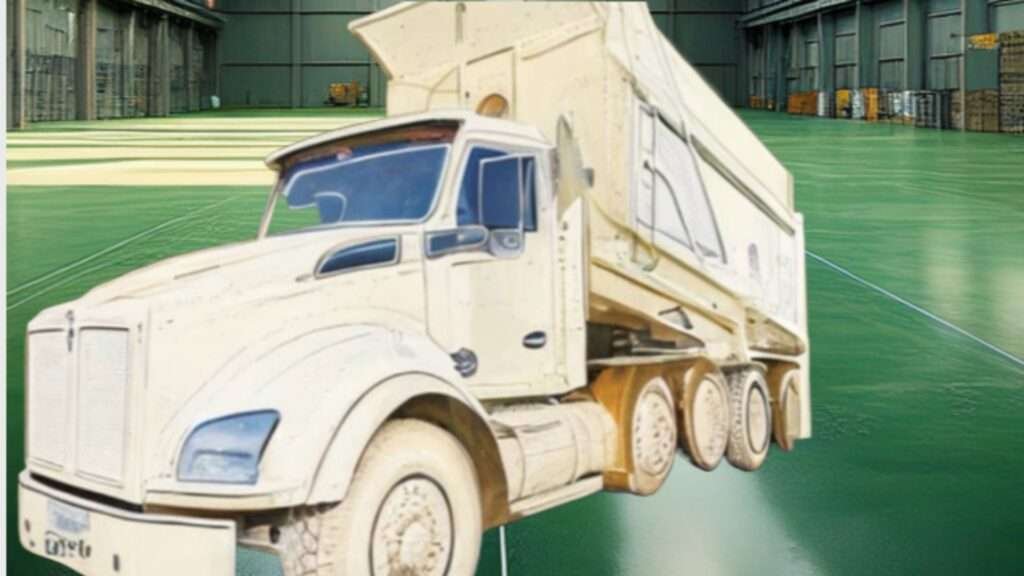

Highway Truck Maintenance Management.

With this article, I hope to convey to you what

you should consider when developing a Maintenance Management Programme for a

Highway Tipper Truck.

I will use the 2021 Kenworth T880 Tipper as the

basis for this article and present it as more of an overarching level of

detail. I will support this article with all of the ‘nuts and bolts’ details

you might be looking for through this document: Truck

Asset Management Plan Details.

As many people are aware, being a truck

owner/operator entails a wide range of responsibilities.

Taking proper care of a truck that is your sole

source of income is critical to ensuring its longevity and optimal performance

while paying your regular bills and, of course, caring for your family.

Let us now look at the asset management

requirements of the aforementioned legendary Tipper.

Over the course of this document and the

previously mentioned ‘details’

document, I’ll be focusing on the features and

benefits of this high-quality truck, as well as what’s required to keep it in

good condition throughout its asset life.

I’ll assume that your T880 Tipper has a Cummins

X15 engine, which is a well-known 14.9-liter inline-six diesel engine, as well

as the incredibly dependable and well-known Allison 7-speed automatic

transmission, which is a superstar gearbox in my book.

Plenty of Comfort and Convenience

In The Cab.

The T880’s cab is thoughtfully designed to provide

comfort during long hours on the road.

The come standard with adjustable air-suspension

seats and lumbar support, you can find the perfect position for maximum comfort

very quickly.

Additionally (as you would expect with Kenworth),

these trucks offer climate control through air conditioning and heating, ensuring

all-weather comfort for the driver.

Routine Maintenance Suggestions

for the Cab of a T880 Tipper.

1.

Air Suspension Seats: Regularly inspect the air suspension seats

for any signs of wear, damage, or leaks.

Lubricate moving parts as recommended by the manufacturer. Check the air pressure and adjust it

according to the rider’s weight for optimal comfort and support.

2.

Air Conditioning and Heating: Clean or replace the cabin air filter

periodically to ensure efficient airflow.

Get a qualified AirCon Tech to inspect the climate control systems for

any leaks, damaged hoses, or malfunctioning components around every 4-6 months. Have these technicians verify that both

heating and cooling functions are working correctly.

3.

Instrumentation & Electronics: Keep an eye on the dashboard instruments,

including gauges, warning lights, and displays.

Address any malfunctioning indicators promptly. Regularly check the functionality of the

infotainment system, navigation, and other electronic features.

4.

General Cabin Maintenance: Clean the interior regularly to prevent dust

build-up and maintain a comfortable environment. Cleaning your Cab on a regular basis helps

with keeping the Air Conditioning System optimal as well. Inspect the upholstery, flooring, and cabin fixtures

for wear or damage. Lubricate hinges,

locks, and handles as needed.

Enhanced Safety Features.

The 2021 Kenworth T880 when configured as a Tipper

Truck is an absolute masterpiece of engineering and is equipped with various

safety features that prioritise the well-being of the driver and other road

users.

These trucks boast sound insulation to minimize

road noise, allowing for a quieter and more focused driving experience.

They also have complex reflector halogen

headlights provide excellent illumination, ensuring optimal visibility during

night time driving.

LED marker lights further enhance visibility,

making the truck easily noticeable on the road. The integrated turn signals in

the mirrors and reverse lights add an extra layer of safety during manoeuvring

and reversing.

Routine Maintenance Suggestions

for these safety features.

1.

Halogen Lights: Keep the lenses clean and free from dirt,

debris, and road grime. Regularly

inspect the bulbs for signs of dimness or discoloration and replace any faulty

bulbs promptly. Please be sure to avoid touching the bulbs with bare hands, as

oil from your skin can reduce their lifespan.

2.

LED Marker Lights: LED lights generally have very long lifespan

and should require little effort on your part.

Inspect the wiring and connectors for any damage or corrosion around

once per year. I would also ensure that

the seals around the lights are intact to prevent water ingress.

3.

Turn Signals: Check the turn signal bulbs regularly and inspect

the flasher relay and wiring connections.

Keep the lenses clean and replace any cracked or damaged lenses.

4.

Mirrors: Clean the mirrors regularly to maintain

visibility and naturally adjust the mirrors properly to minimize blind spots. Inspect mirror brackets and mounts for

stability and corrosion at the base attachments.

5.

Reverse Lights: Clean the reverse light lenses to ensure

maximum brightness. Inspect the wiring

and connectors and maybe consider upgrading to LED reverse lights for improved

longevity.

6.

Reverse Alarm: The backup alarm (reversing alarm) alerts

others when the truck is in reverse and is an important safety feature. It’s important to give it a regular test to

ensure it’s functioning correctly and avoid a rather nasty situation. Keep the alarm clean and free from debris.

Convenience and Connectivity on

board your Kenworth T880.

I’m sure most modern truck drivers rely heavily on

the various technologies we now have to stay connected and entertained on the

road.

The very reliable Kenworth T880 Tipper is no

exception and offers an array of infotainment system options, including a

quality radio, Bluetooth connectivity, and navigation capabilities. They also

started coming standard with a 15 inch digital display system as well.

The informative instrument cluster provides clear

displays for all essential information, allowing the driver to stay informed at

all times. Power outlets are also conveniently included, ensuring that devices

can be charged during long hauls.

The steering wheel is equipped with controls for

audio, cruise control, and other functions, providing easy access to essential

features without distractions.

Maintenance Ideas for the Convenience

and Connectivity Features.

1.

Infotainment System: The infotainment system, including the radio,

Bluetooth connectivity, and navigation, enhances the driving experience. While there are no direct maintenance

requirements for these features, here are some best practices: Keep the display screen clean to ensure clear

visibility. Regularly update the

navigation maps (if applicable) to stay accurate. Pair your Bluetooth devices securely to

prevent connectivity issues.

2.

Power Outlets: The

power outlets are essential for charging devices like phones, tablets, or

laptops. Inspect the outlets

periodically for any damage or loose connections. Ensure that the fuse protecting the outlets

is functioning correctly.

3.

Cruise Control: Cruise control naturally helps maintain a

consistent speed on highways. No

specific maintenance is required for cruise control itself. However, ensure that the vehicle’s overall

engine and transmission maintenance is up-to-date for optimal performance.

4.

Audio System Functions on Steering Wheel: These controls allow you to adjust volume,

change tracks, and manage calls without taking your hands off the wheel. Inspect the buttons for wear or damage. Keep the steering wheel area clean to prevent

dust build-up.

Sustained Performance with your

2021 Kenworth T880.

As you would expect with anything that has the

Kenworth badge, these trucks are renowned for their exceptional performance and

reliability.

With a Cummins X15 engine and an Allison 7-speed

auto transmission, these trucks deliver plenty of power and efficiency.

Typically, the front Bridgestone tires are sized

at 385/65R22.5, while the rear tires are 11R24.5, offering optimal traction and

stability on various terrains.

These features, combined with the truck’s sturdy

construction and durable components, make it a top choice for truck owners/operators

who prioritise quality and performance.

Taking Proper Care of Your Bridgestone

Tires.

1.

Proper Inflation: Regularly check and maintain the correct tire

pressure. Under-inflated tires can lead to premature wear and reduced fuel

efficiency. Follow the manufacturer’s

recommended pressure for your specific load and application.

2.

Rotation: Rotate the tires regularly to ensure even

wear across all axles. Front and rear

axle tires wear differently, so rotating them helps extend overall tire life.

3.

Alignment and Balancing: Proper wheel alignment prevents uneven wear. Balancing ensures uniform weight

distribution, reducing vibrations and extending tire life.

4.

Avoid Overloading: Exceeding the tire’s load capacity can cause

excessive wear and damage. Ensure that

the truck’s weight distribution complies with the tire specifications.

5.

Inspect for Damage: Regularly check for cuts, punctures, bulges,

or sidewall damage. Remove any embedded

stones or debris to prevent further harm.

6.

Driving Habits: Avoid sudden stops, aggressive acceleration,

and sharp turns. Smooth driving reduces

stress on tires.

Should

I Replace Tyres With Retreads Or New Tyres?

I fully understand that sometimes, things are

tough and we need to make some tough decisions around routine Truck Costs.

I would just like to say though, when it comes to

deciding between new truck tires and retreaded truck tires, there are several

factors to consider and I will just offer info, not implied directive.

What Are The Typical Advantages

Of Retreaded Tyres for Trucks?

Cost-Effective: Retread

tires are generally cheaper than new tires and since they reuse the existing

tire casing, the cost savings can be significant.

Environmental Benefits:

Retreading reduces the carbon footprint. A study found that retreading light

commercial vehicle tires can reduce carbon dioxide emissions by approximately

26.4 kilograms (58.2 pounds) per tire.

Safety: Modern

retreading processes adhere to high standards of quality, ensuring that retread

tires are safe and reliable.

What Are The Normal Advantages Of Using New Tyres On

Trucks?

When it comes to highway trucks, opting for new

tires over retreaded ones is generally considered a safer and more reliable

option.

Below are just a few reasons for

this.

Tyre Integrity: New tyres

are manufactured with fresh materials, ensuring their structural integrity.

They have no history of wear, damage, or previous use. In contrast, retreaded

tires reuse the existing casing, which may have hidden issues or wear from

previous usage.

Safety Concerns: Large

trucks operate under demanding conditions, carrying heavy loads and travelling

long distances. Safety is paramount.

New tyres provide consistent performance, better

traction, and improved handling. They are less likely to experience blowouts or

tread separation.

Quality Assurance: New tyres

undergo rigorous quality control during manufacturing. They meet industry

standards and are thoroughly inspected.

Unfortunately, retreaded tyres also have quality

checks, but there’s always some uncertainty about the condition of the original

casing.

Tread Depth: New tyres

start with full tread depth, providing better grip on wet or slippery roads.

As you might expect, retreaded tyres may have

shallower treads due to previous wear, affecting their performance in adverse

conditions.

Longevity: While

retreaded tyres offer cost savings, they have a limited lifespan. New tyres

typically last longer, reducing the frequency of replacements and maintenance

downtime.

Peace of Mind:

Choosing new tyres provides peace of mind for truck operators and fleet

managers. You know exactly what you’re getting, and there are no hidden

surprises.

Possible Tyre Casing Wear:

Even if the old tyre casing is in good condition, some wear has likely occurred

in its cords and infrastructure. This wear may lead to issues down the road.

Limited Lifespan Of Retreads:

While retreads can extend the life of a tyre, they still have a finite lifespan

compared to new tyres.

Replacement Tyre Brand Variety:

If you choose new tyres, you’ll have a wide variety of brands and types to

choose from.

This allows you to find the perfect fit for your truck

fleet’s specific needs.

When you opt for a retread, you will possibly just

receive that applicable option that the garage or tyre business has available.

Tyre Longevity: New tyres

typically offer a longer lifespan compared to retreads.

Ultimately, the all important

tyre decision depends on your priorities.

If times are tough and cost savings are paramount

and environmental impact issues are on your mind, then retread tyres may be a

good choice.

However, if you prioritise longevity then always

replacing old tyres with new might just be

the better fit for your needs.

Consider your budget, safety requirements, and

fleet usage when making the decision. And remember, professional advice from

experts in the industry can help guide your choice

How to Store Your Spare Truck

Tyres?

Only ever store your spare tires in a cool, dry

place away from direct sunlight. Avoid

stacking tires or placing heavy objects on them.

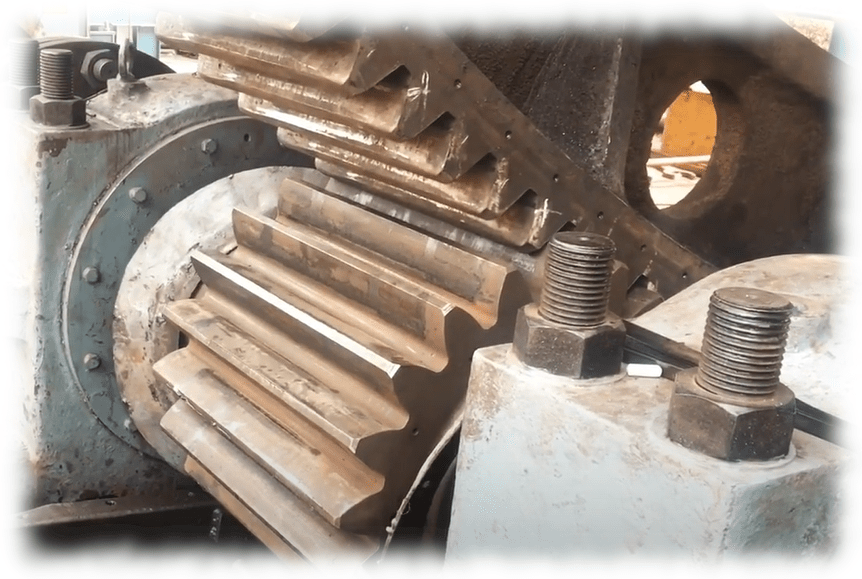

Cummins X15 Engine and Allison

7-Speed Auto Transmission Basics.

As I mentioned at the start of this document, you

will find some very detailed information for looking after this

model/type/configuration of truck on The

Maintenance Details Document.

In

a nutshell though, be sure to consider the following tasks.

1.

Regular Oil Changes: Follow the manufacturer’s recommended oil

change intervals for both the engine and transmission. Use high-quality oil that meets Cummins and

Allison specifications.

2.

Coolant and Filters: Maintain proper coolant levels and replace it

as needed. Change fuel filters, air

filters, and transmission filters at recommended intervals.

3.

Fluid Levels: Regularly check transmission fluid levels and

top up if necessary. Monitor engine

coolant levels and address any leaks promptly.

4.

Be Sure To Avoid Overheating: Ensure proper cooling system function. Monitor engine temperature and avoid

prolonged overheating.

5.

Inspect Belts and Hoses: Check for wear, cracks, or leaks in belts and

hoses. Replace any damaged components

promptly.

6.

Monitor Gauges and Alerts: Pay attention to dashboard gauges and warning

lights. Address any abnormal readings

immediately.

7.

Enging Using Habits: Although I have almost certainly mentioned

this top earlier in this article it is just so important to avoid excessive

idling or aggressive driving over the course of a diesel engine. Allow the engine and transmission to warm up

before heavy loads and try to only use them under load.

Remember that regular maintenance and attentive

care are crucial for maximizing the life of both your Bridgestone tires and the

Cummins X15 engine with the Allison transmission

Proper Asset Management For Your Kenworth

T880 Dump Truck,

Proper asset management/maintenance is essential

for truck owners/operators to ensure the longevity and optimal performance of

their vehicles.

These particular trucks offer a comprehensive package

of comfort, safety, convenience, and performance features that make it a

standout choice in the market.

By understanding how these trucks best work and

doing to bit of research to help you make sure that you implement the best necessary

maintenance practices, you can maximize the value and efficiency of your

investment in this style of quality truck.

Sustaining Asset Management

Framework For Your Truck.

The first step is just determining the Asset

Management Framework for your 2021 KENWORTH T880 Dump Truck.

It’s a complex task but roughly speaking, managing

a highway truck, such as the 2021 Kenworth T880 Tipper, requires a steady and

consistent approach towards care and maintenance that ensures safety,

reliability, and cost-effectiveness.

To achieve these goals, it is essential to

implement an overarching asset management framework that encompasses

assessment, planning, execution, and review and adaptation.

Then look at each of the more specific and key

components that are of significance for successfully maintaining and optimising

the performance of your truck.

a)

Perform an Assessment and evaluate the

truck’s overall condition.

This involves a thorough evaluation of various aspects, including the

engine, transmission, suspension, brakes, tires, and overall structural

integrity.

·

By conducting a comprehensive

assessment, you can identify areas that require improvement or immediate

attention.

·

During the assessment, it is

crucial to pay close attention to any signs of wear and tear, leaks, or

abnormal noises.

·

Additionally, monitoring the

truck’s performance through regular inspections and maintenance records can

provide valuable insights into its overall health.

·

By identifying potential issues

early on, you can prevent major breakdowns and minimize downtime.

b) Develop

a Long-Term Strategy:

Once you have assessed the condition of your dump

truck, the next step is to develop a long-term strategy for its maintenance,

upgrades, and replacements.

·

This planning phase involves

creating a roadmap that outlines the necessary actions to keep your truck in

optimal condition and extend its lifespan.

·

Consider factors such as the

truck’s usage patterns, anticipated workload, and industry regulations when

developing your strategy.

·

This will help you determine the

frequency of maintenance tasks, such as oil changes, filter replacements, and

brake inspections.

·

Additionally, it is essential to

plan for potential upgrades or replacements of critical components to ensure

the truck’s continued performance and compliance with evolving standards.

c)

Implement Your Asset Management Plan

Consistently:

Execution of your plan on time, in full and at

specification is the most important aspect of asset management.

·

It’s the phase where you put your

plan into action.

·

Doing quality maintenance

consistently when it should be done and in the way it should be done is

essential.

·

Ensure that the maintenance

tasks, upgrades, and replacements are carried out as scheduled.

·

Adhering to a regular maintenance

schedule and following manufacturer guidelines for servicing will help optimise

the performance and reliability of your dump truck.

·

During the execution phase, it is

crucial to keep detailed records of all maintenance activities, repairs, and

component replacements.

·

This documentation will not only

help track progress but also serve as a valuable resource for future reference

and decision-making.

d) Review

& Adaptation, Monitoring Performance & Staying Informed:

Regularly reviewing the performance of your dump

truck is vital to identify any areas that may require adjustment or

improvement.

This includes monitoring fuel efficiency,

analysing maintenance costs, and evaluating the truck’s overall reliability. By tracking these metrics, you can make

informed decisions about potential modifications to your asset management

strategy.

Furthermore, staying informed about industry

advancements, technological innovations, and regulatory changes is crucial to

adapt your asset management framework accordingly.

New technologies, such as telematics systems and

predictive maintenance tools, can provide valuable insights into the health and

performance of your dump truck, enabling proactive maintenance and minimizing

downtime.

A Comprehensive Asset Management

Framework Will Serve You Well.

An overarching asset management framework is

essential for effectively managing a 2021 KENWORTH T880 Dump Truck.

By following the assessment steps, doing the

maintenance planning, always executing your planned maintenance completely, then

reviewing your regular results and then adapting to your learning’s is the key.

This is the way you will best ensure maintenance safety,

Truck Reliability and overall cost-effectiveness of your small business (your

truck).

Regular maintenance, strategic upgrades, and

staying informed about industry advancements will help optimise the performance

and extend the lifespan of your dump truck, ultimately maximizing your return

on investment.

Your next step is to read up on the individual

tasks that will make up your T880 Tipper asset management/maintenance strategy.

As mentioned a few times throughout this document,

you can reach this information via clicking

on this link.